Brake shoes are parts that act on the axle or against the wheel in order to moderate or slow down the movement of the vehicle by friction.

These are metal, curved-shaped elements, which are composed of a friction material fixed on their side. These parts that make up the drum brake are used on the rear axle. This is because most vehicles brake sharply with their front wheels. In the case of the rear, the drum brakes, being located at the rear, do not handle such high temperatures.

Brake shoes are part of the drum brake system. But, do we know exactly what they are used for? In this post by Frenkit, specialist in the manufacture and distribution of brake components, we explain everything you need to know about brake shoes and when they need to be replaced. Are you going to miss it?

What is a brake shoe and what is it used for?

The brake shoes are responsible for pressing the inner face of the drum and thus generate the friction necessary to stop the vehicle.

Its operation is very simple: as drivers, when we press the brake pedal, we force the brake shoe to exert pressure on the wheel cylinder, which comes out, hitting against the inner part of the drum. This impact ends up generating friction and brings the vehicle to a stop.

The drum brake system is recommended for compact and mid-range cars, where the brake pads have a useful life of approximately 100,000 kilometers.

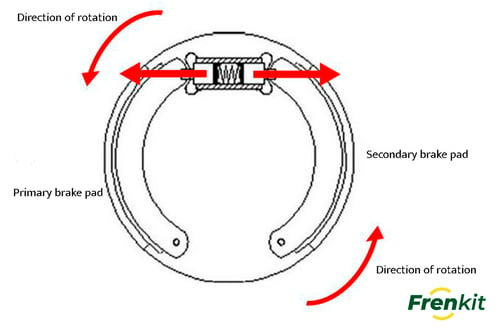

In addition, there are two types of brake shoes. Both are composed of two steel plates welded together in a crescent shape and are usually covered with brake linings on the outside, which join the metal brake shoes by gluing or riveting.

- Primary brake shoe. Located in the direction in front of the car, it is in charge of applying a greater force on the side against the rotation, thus causing a greater friction.

- Secondary shoe. It exerts greater force on the side in favor of the rotation, so its friction is lower.

When to change brake shoes

As they are encapsulated by the brake drum, i.e. the visible outer part of the brake system, the brake pads are quite complex to replace and disassemble. To do this, it is important to remove the drum brake for easier access to the brake shoes. The next step is to remove the rest of the components that hold the other parts.

As in most of the elements of our car, the wear and replacement of the brake shoes will depend on the type of use or frequency with which we drive our vehicle.

Generally, brake shoes do not require constant maintenance, since the part that most often breaks down is the cylinder, an element that performs the lateral displacement of these parts for braking the drum. However, there are some indicators that show us that it is necessary to change or replace the components of the drum brake of our vehicle:

Wear and tear on vehicle components

As we have already explained above, the wear suffered by the drum brakes may be due to the way we drive or the maintenance we are giving to our vehicle, being these some of the indicators for which we should replace the brake shoes.

In turn, when a noise is produced when braking the car, this may be due to the drum brake suffering from deformation or irregular wear.

Burnt smell

In the event that we brake very hard and we perceive smoke and a burning smell, both indicators are clear examples that the drum shoes have overheated.

If this happens, it is essential to go to a generalist or specialized drum brake workshop where they can carry out an overhaul of our brake system.

Longer brake pedal travel

If it happens that the travel when the brake pedal is depressed is longer, this may be because the brake shoes have lost, or are losing, efficiency, which in turn leads to wear within the drum brake elements. Therefore, it is vitally important to take care of both the brake shoes and the drum brake components as a whole.

To avoid excessive wear of the brake shoes, at Frenkit we recommend acquiring parts made of resistant materials such as steel or metal, as is the case of our drum brake repair kit.

All our brake parts and components are manufactured according to OEM or customer specifications, with a quality management system certified according to ISO 9.001 requirements.

In addition, on our website we give you the possibility to access the online store where you can choose from more than 9,000 references of brake system components and filter by different types of products.