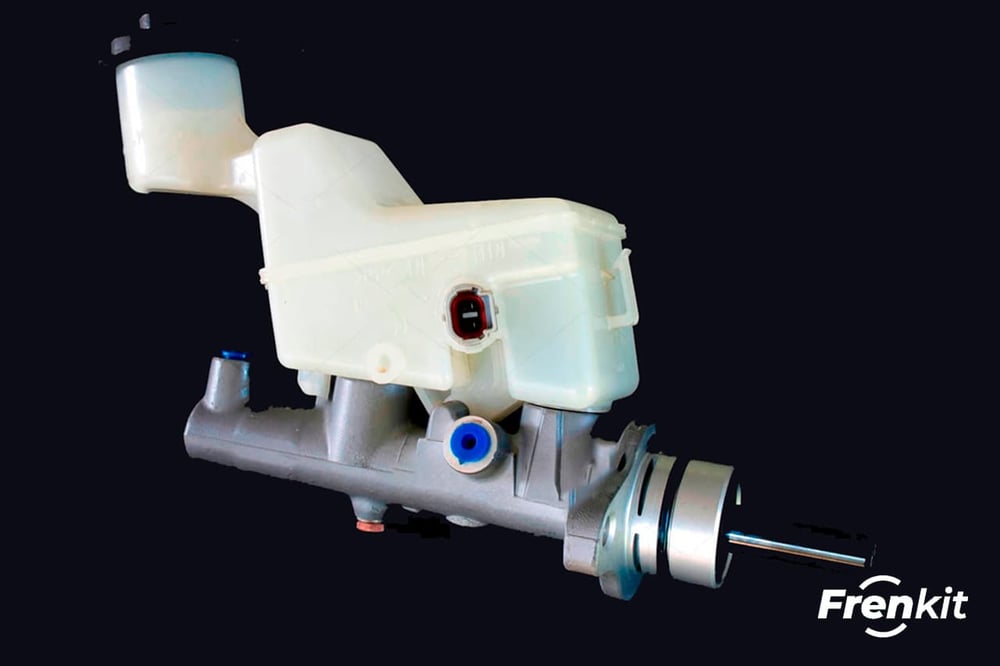

Brake pumps or master cylinders are a vital component for the safety of our vehicle. Thanks to the brake pump and the force that the brake fluid exerts on the various elements of the brake system, we are able to bring the vehicle to a halt.

In this Frenkit post, we are going to discover what the different types of brake pumps or master cylinders are and each of their components. But first, let's remember the definition of a brake pump or brake master cylinder:

“The brake master cylinder is the component responsible for pressurising the fluid or maintaining pressure throughout the vehicle's hydraulic circuit”.

Types of brake pumps or master cylinders

We may have seen, on occasion, different types of brake pumps that are very different from each other. However, we need to know that they all work in a very similar way.

Pumps or master cylinders can be of two types: single brake pump (single chamber) and tandem brake pump (with two chambers).

In turn, we distinguish two models according to the construction of the master cylinder: solid brake master cylinder and composite brake master cylinder. The former, the solid brake master cylinder, consists of a single part, while the composite brake master cylinder comes with a separate reservoir.

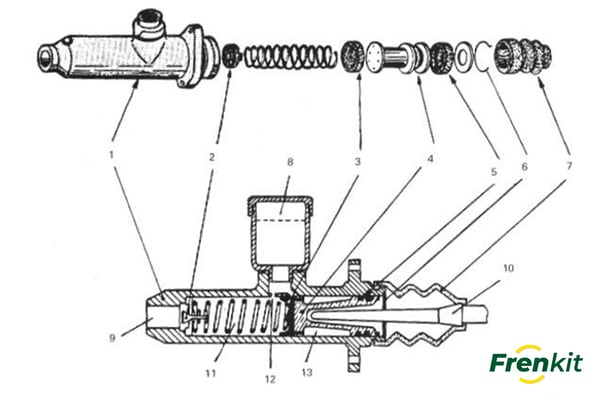

Single brake pump

Single pumps are fed with fluid from the reservoir, which passes through the master cylinder and into the brake lines. Inside the single brake pump is the plunger or piston which is responsible for generating the hydraulic force by means of the force exerted by the driver on the brake pedal.

When the force on the brake pedal disappears, the plunger returns to its initial position by spring action.

The parts of which the brake pump or single master cylinder is composed are:

- Cylinder.

- Double-acting valve.

- Primary rubber.

- Piston.

- Secondary rubber.

- Insurance.

- Dust cover.

- Reservoir.

- Fluid outlet port.

- Push rod.

- Chamber.

- Equalisation hole.

- Chamber.

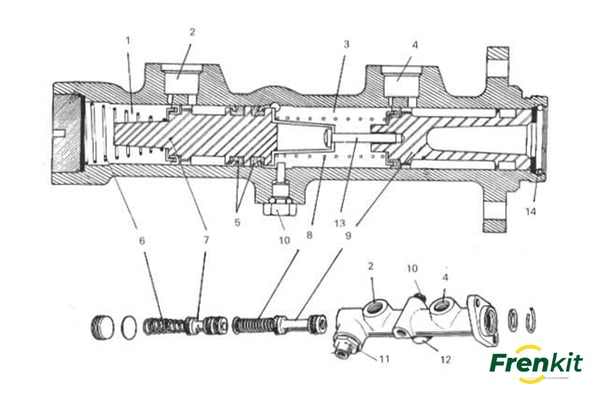

Tandem brake pump

The tandem brake pump, consisting of two pistons placed one after the other, allows a better distribution when braking our vehicle, as each circuit is responsible for a pair of rims. These chambers are actuated by two pistons.

Various distributions can be found, although the most common is in the form of an X, where the front wheel on one side is connected to the rear wheel on the other side or vice versa. It may happen that one of the two circuits does not work properly: in this case, the other circuit may still work to bring the vehicle to a stop. In this situation, the braking distance increases considerably.

With regard to the parts that make up the tandem brake pump we find:

- Primary piston.

- Secondary piston.

- Primary piston assembly screw and also holding the spring positioning box.

- Recovery spring guide.

- Primary recovery spring.

- Secondary recovery spring.

- Primary circuit lock washer and primary cupel.

- Secondary circuit lock washer and primary cupel.

- Secondary primary circuit secondary dome.

- Secondary circuit secondary dome.

- Sealing flange between the primary and secondary circuit.

- Screw with copper gasket.

- Secondary piston idle stop.

- Clip and stop washer.

In conclusion, we can point out that the master cylinder is the key element responsible for the braking system of our vehicle. For this reason, it is essential to know how it works, as well as its component parts.

At Frenkit we are a company specialised in the manufacture and distribution of brake pump components. We have a catalogue with more than 9,000 references that we distribute in more than 50 countries. Visit our website and discover our online shop with a wide variety of spare parts for your vehicle.

![[Find out which is better, repairing a brake caliper or replacing it completely]](https://no-cache.hubspot.com/cta/default/7520036/1c669645-1e7f-4c24-a3ba-30d135d9ac2a.png)