Within the braking system of a vehicle, the handbrake is an essential element, as it is used when we want to bring our car to a complete stop.

Automation is gradually becoming more and more important in our daily lives. In the case of cars, it offers even greater advancement. Since its introduction to the market in 2001, the electric parking brake system has become an increasingly popular feature in new vehicle models.

A car’s handbrake is a wheel-locking mechanism designed to keep the vehicle stationary. This is the quintessential handbrake, the mechanical handbrake, which is fitted to every vehicle on the market. However, over time, this mechanism has evolved, giving rise to the electric handbrake.

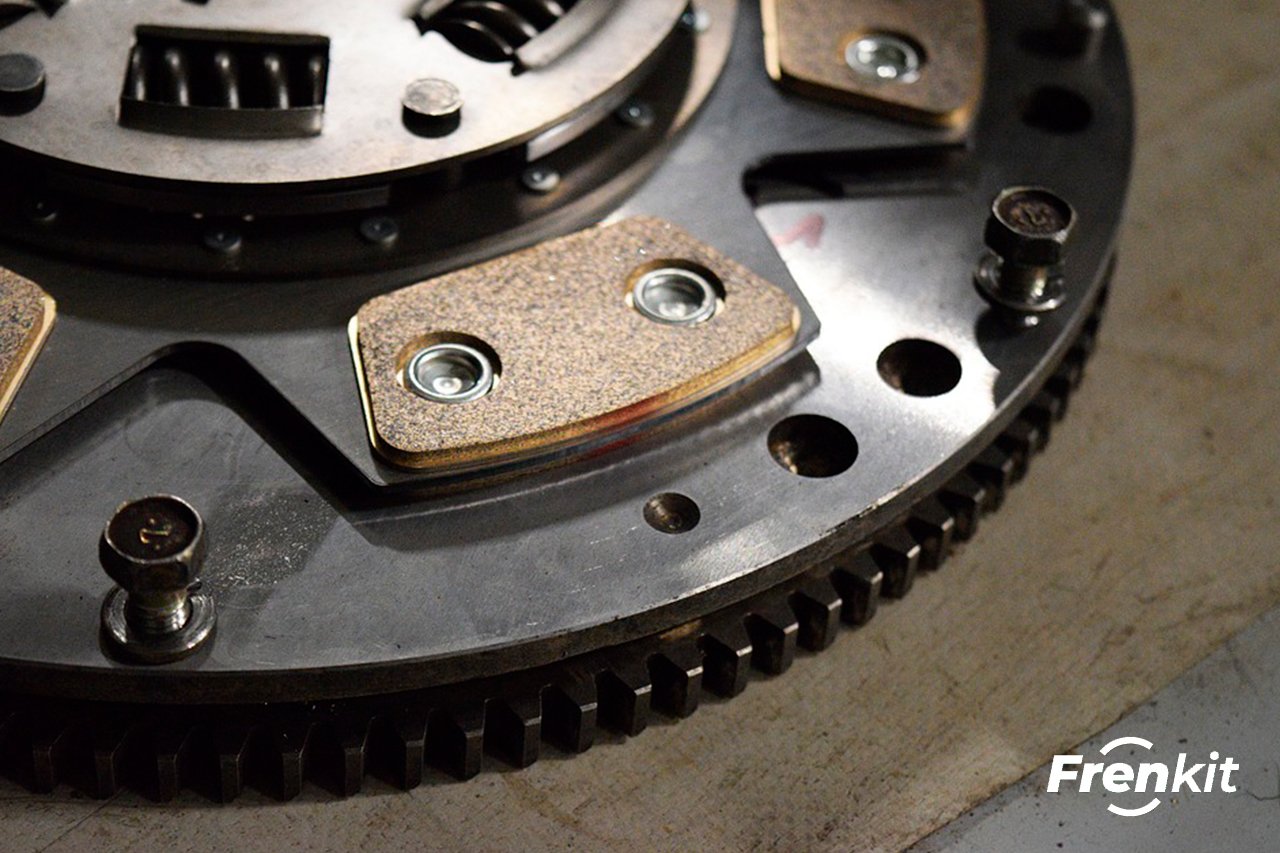

The clutch master cylinder is located near the clutch pedal motor outlet. It is a very simple hydraulic cylinder that is connected to the clutch pedal of our vehicle and to the impeller of this pedal by a hose full of oil.

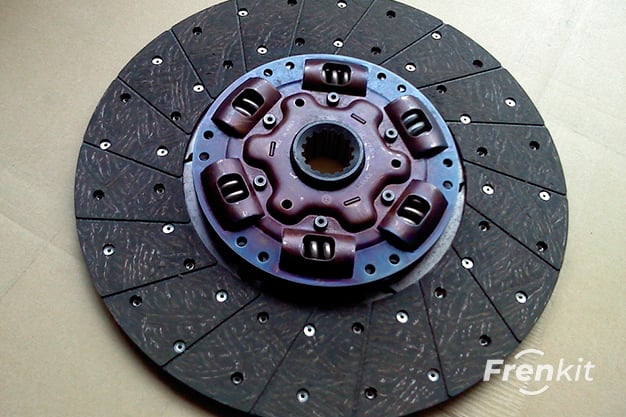

The main purpose of the clutch system is to isolate the movement of the engine from the wheels while driving a changing gears. Thanks to the clutch, we can achieve the correct transmission of the engine power from the gearbox, which is then transferred to the vehicle’s wheels.

What is a clutch in a car? The clutch of the combustion car is a system that we use continuously when we drive, for this reason it is an indispensable part for the correct operation of our vehicle. Without this system we would not be able to change gears or drive.

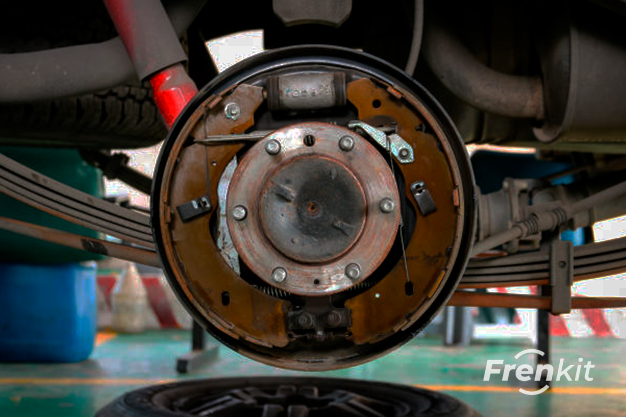

Brake shoes are parts that act on the axle or against the wheel in order to moderate or slow down the movement of the vehicle by friction.

Airbags, to avoid impacts when crashing; or the Anti-lock Braking System (ABS), which prevents the tires from losing their grip on the road. These are some of the safety elements in vehicles that are always taken into account. But we cannot forget one of the most important systems: the brakes.

When we press the brake pedal to stop our vehicle, the brake system absorbs the kinetic energy produced in its displacement. This movement is carried out by friction between two parts: a fixed part, such as the brake shoes; and a moving part, such as the drum.

The drum brake is characterized as a type of braking system that, when the brake pedal is applied, produces friction through the brake shoes, which also press against the inner surface of a rotating drum that is connected to the axle or wheel of the vehicle.

Drum brakes have become an indispensable part of any vehicle's braking system, as they are perfectly adapted to both highways and back roads, as well as adverse weather conditions.

The drum brake is composed of several elements such as: the outer and inner part of the brake drum, brake plate, brake shoes, hydraulic cylinders and a reset system.

Although it is an overlooked part on older or second-hand cars, the drum brake is a braking system that is still in full use on today's cars, not to mention commercial and industrial passenger cars.

The drum brake is a fundamental part of the braking system of our vehicle and as such is responsible for ensuring our driving safety.

Drum brakes are applied when a vehicle 's brake pedal is depressed. The system presses hard on the brake shoes, which is coated with a special friction material.